Tapered sliding dovetails, positive and negative halves.

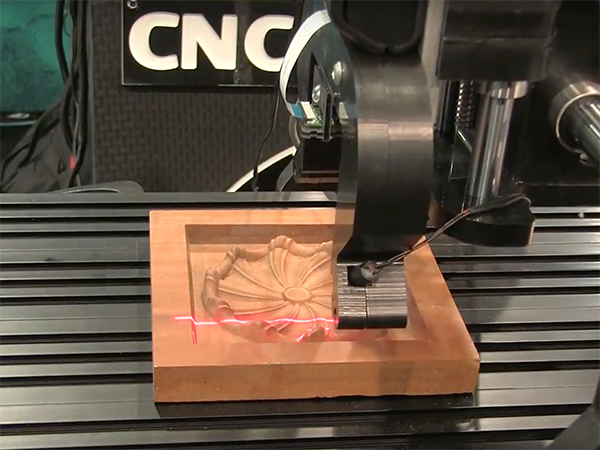

PIRANHA CNC DOVETAIL JOINTS CODE

The round shape of each bit and length of the cutting edge are the only limitation, but results can be as varied as your name in through-fingers, Morse code in dots and dashes as through fingers, or geometric patterns or progressions as through fingers. A pattern drawn for the positive side of a joint can be used with only a little modification to make the negative pattern for other side. But now that you can make box joints with the precision and control of a CNC, the different sizes of router bits available present options for amazing creativity in the shape of the interlocking fingers. Once you are able to cut vertically on a CNC an obvious joint to make is the box joint. I made a 5-sided box with the dovetails laid out to spell my name in Morse code just to inspire the students. This joint can also be cut for 72 degree (5 sides) and 60 degree (6 sides) corners. The CNC solution came to me one night and required making a jig to hold his panels under the CNC at 45 degrees, and once we had that we could cut both halves of a slight variation that looks exactly like the original example. He had found a photo example online, and as far as my research got it looked as though you could use a jig on the router table to cut half of this joint, but the other half would need to be hand cut. This half blind dovetail example was a request from a student in my CNC focused furniture joinery class.

This sloped intersection wedges out as the parts are clamped in, leaving them very tight inside the hole. My angled through scarf lap joint maximizes side grain glue surface, maintains strength at the ends of each half, and is invisible once glued together. The result from all of these options is a joint that is weaker than the original strength of the through piece. You could make short tenons on each cut end and mortise them half way into the wider board. Or half-lap the through board inside a hole cut through the wide board. Cut the through board and pass a dowel through the larger piece into these cut ends. When a small board penetrates the center of a wider board the options are limited. If a smaller piece is at the edge of a larger piece you can still interlock both with cuts into their edges. If the same size they can be half-lapped. Often a project requires one board to appear to pass through another. This pattern can be scaled up or down to match the width of your stretchers, and is only limited in height, diameter, or by the length of the bit you'll use to cut it. You cut the same profile on the ends of each piece from the top. vertical stiffness, and still locks the three elements together within that small area. My 3-way interlock maximizes glue surface area, maintains through-grain structure. A 3-layer "stack" would work, but removes 2/3 the thickness off each stretcher, and leaves the center piece needing to be cut on both sides or from the top. The simplest way at first could bring them to meet at the very center, except there is only a small area of intersection you can make a 3-way joint within. You could bring them into a center hub piece. You can bring stretchers to the middle, pin wheeling them to each touch the other two. You can run stretchers from leg to leg around the perimeter. When 3 legs need to be connected with a stretcher there are only a few options. We have our advanced students design and build a 3-legged (or fewer legs) stool during the first two weeks of class.

0 kommentar(er)

0 kommentar(er)